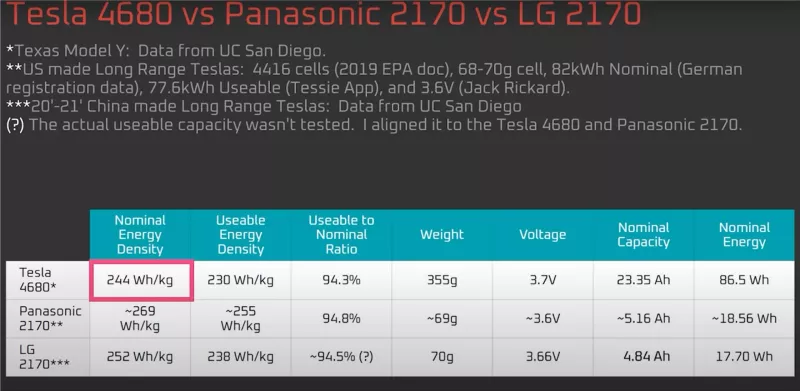

A video clip posted by The Limiting Factor YouTube declares that Tesla's 4680 battery cells have less energy density and more cobalt than the 2170 battery cells used by the Tesla Model Y.

Tesla's 4680 battery cells assembled in Austin for the Tesla Model Y are made up of regular ol' NMC ternary chemistry, with the only difference being that they are more significant, as was disclosed in two videos released to YouTube in September by the Munro Live and The Limiting Factor channels. A new video from the second of these channels confirms that these battery cells aren't as good as they could be because they have less energy density and more cobalt.

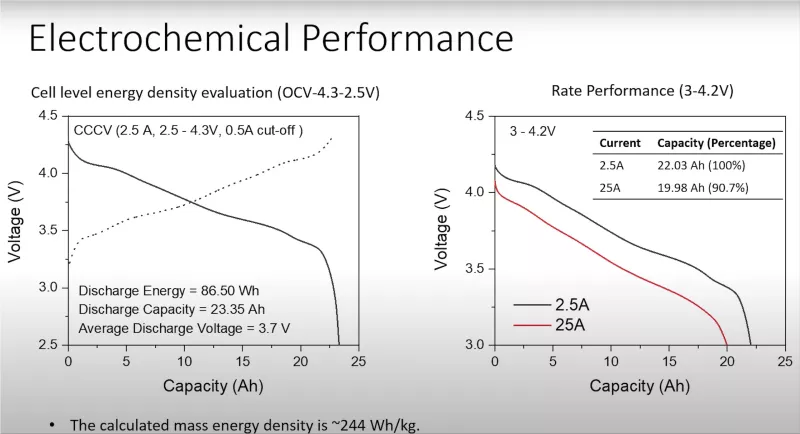

A study by UC San Diego found that the Austin, Texas-produced Tesla Model Y's 4680 battery cells have a lower energy density (244 Wh/kg) than the Panasonic 2170 battery cells powering the Fremont-assembled Model Y and the LG cells powering the Shanghai-produced Tesla Model Y and Tesla Model 3.