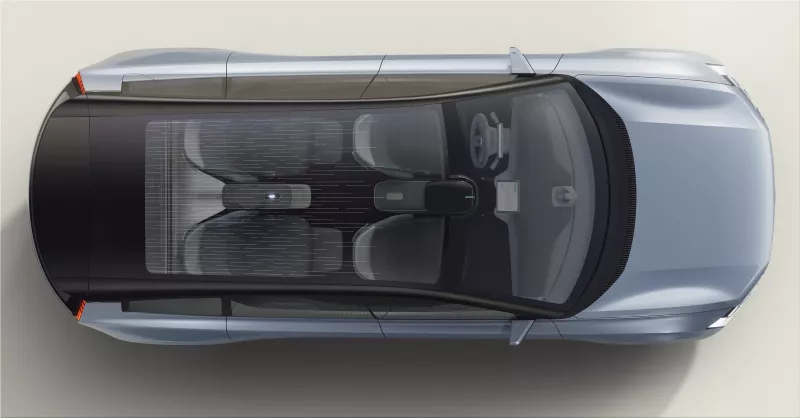

The plan for the next generation of Volvo cars is to become the company's safest ever, thanks to groundbreaking software and hardware combined with constant and faster improvements to safety features using real-time data.

Volvo Cars have always based its approach to safety on accurate traffic data that has been used to develop new safety technologies and make electric cars even safer. For its next generation of electric cars, the company now plans to process real-time data from customer cars if customers provide access, thus helping Volvo Cars improve safety continuously.

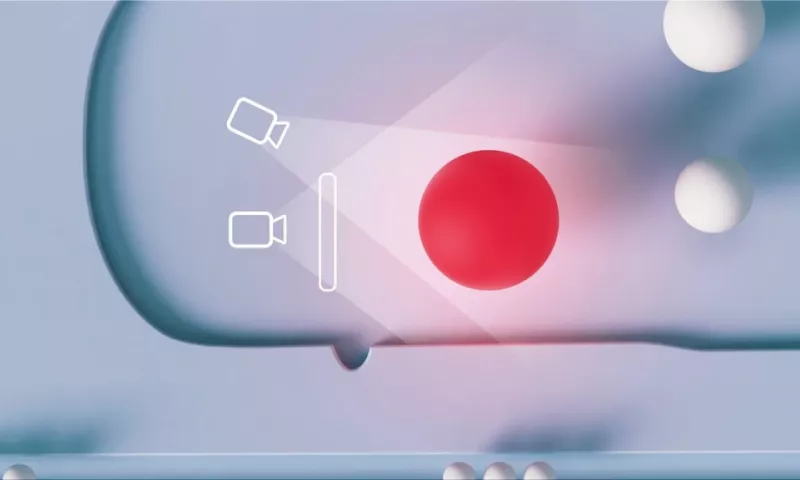

By allowing customers to choose and help improve safety and road safety, Volvo Cars can implement much faster improvements to its electric cars and constantly optimize the level of safety. The plan is for this data to include constant input from the car's surroundings from sensors such as the high-resolution LiDAR from the technology company Luminar.